From first idea to first rideable prototype

The start of Taily dates back to 2017 when we had the first idea for a modern, safe and practical compact cargobike. From that moment we really started working on our mission: ‘creating a premium longtail cargobike.’

The first sketches already gave a good feeling of how the bike would look like. We had a breakthrough insight when we figured a way to combine the frame, luggage carrier and coat protector into one hollistic part. This greatly benefits the stiffness of the frame. The design of the Taily is also super safe and easy to assemble which reduces complexity and costprice altoghether.

“We had a breakthrough insight when we figured a way to combine the frame, luggage carrier and coat protector into one hollistic part.”

— Pieter Hollebrandse

Designing the frame and selection of the components.

After we finished the first prototype we defined our strategic ambition. The starting points of Taily are safety first, clean uncomplicated aesthetics, modularity and built in a modern and local production.

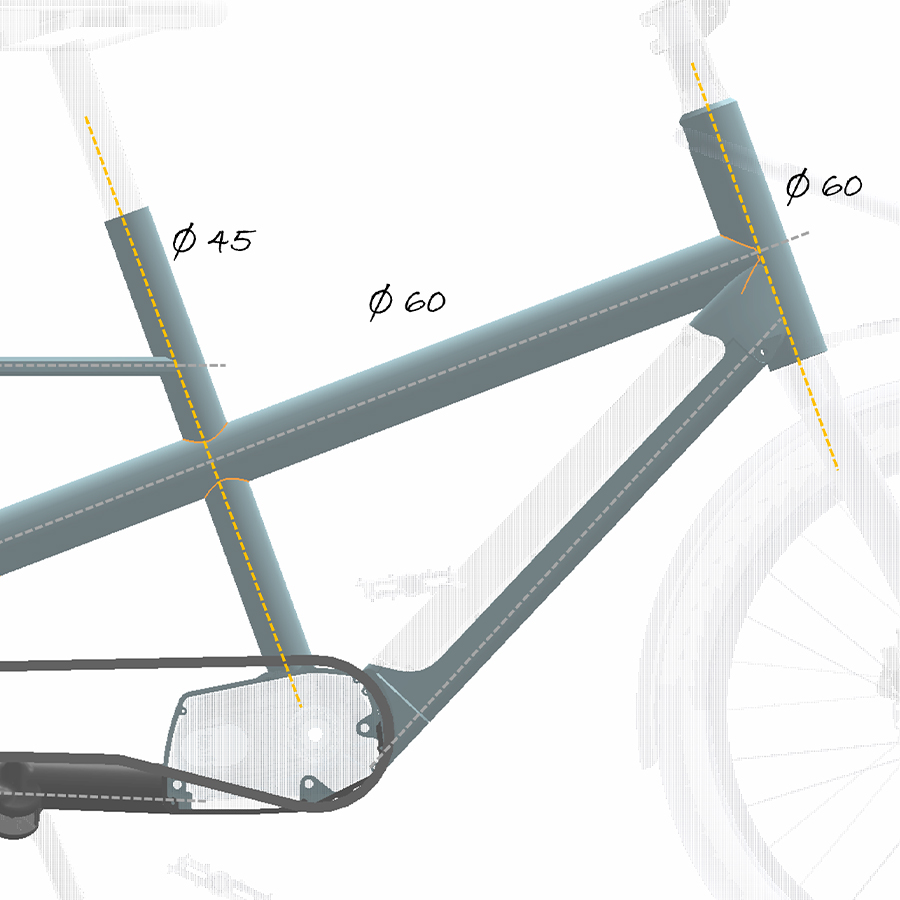

We selected the main components and we designed the frame in detail in 3D CAD. Raw blocks and tubes of aluminium were ordered for the all frame component. These blocks and tubes were (CNC) machined in our workshop. Some complex parts were 3d printed in aluminium.

After creating a welding jig the frame was ready to be welded together. With the welded frame a test fit was succesfully performed, and the frame was sanded smooth and painted perfectly.

From prototype to mass production

Preparing a new concept for mass production takes a lot of time. The prototype has been extensively tested by end consumers, bicycle dealers and experts in the field.

We are currently in talks with several interested manufacturers to prepare the Taily for mass production. Want to know more? Feel free to get in contact.